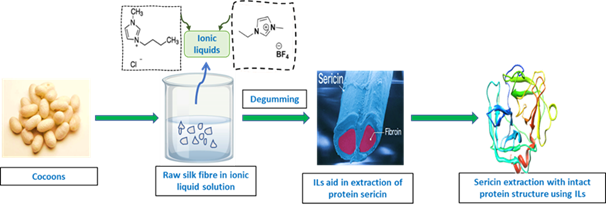

Guwahati: In a breakthrough for the silk industry, researchers have discovered an eco-friendly approach that can eliminate the use of toxic chemicals traditionally employed in silk processing. The team at the Institute of Advanced Study in Science and Technology (IASST) Guwahati, an autonomous institute under the Department of Science & Technology, has identified Ionic Liquids (ILs) as promising sustainable alternatives for extracting silk proteins, fibroin, and sericin from various types of raw silk fibers.

Historically, toxic chemicals such as sodium carbonate, sodium hydroxide, sulfuric acid, and lithium bromide have been utilized to extract these proteins, which are essential in transforming silk from cocoons into usable fibers. The new research, led by Dr. Kamatchi Sankaranarayan, has identified four different ILs that can effectively extract silk proteins without the harmful environmental impact associated with conventional methods.

Published in Chemistry Select by Wiley Publishers, this pioneering study holds significant potential for the silk industry, particularly in the extraction of sericin from both mulberry (Bombyx mori) and non-mulberry silks, such as Muga (Antheraea assamensis) and Eri (Philosamia ricini), which are indigenous to Northeast India.

The research team explored six different ILs and found that some were particularly effective in removing sericin without damaging the silk protein structure. Among these, 1-Butyl-3-methylimidazolium chloride (BMIM.Cl), 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIM.BF4), and Tetraethylammonium bromide (TEAB) showed the greatest promise. TEAB, in particular, was highlighted for its ability to destabilize sericin proteins effectively.

“This new approach not only offers an environmentally friendly alternative to traditional chemical methods but also paves the way for efficient sericin extraction from non-mulberry silks,” explained Dr. Sankaranarayan. “This could lead to new applications for these unique fibers, expanding the versatility and sustainability of the silk industry.”

The discovery marks the first instance of using ILs for sericin extraction from non-mulberry silks, showcasing the potential of this innovative method to transform the industry. By reducing reliance on toxic chemicals, this research supports a more sustainable and diverse silk production process, aligning with global efforts to enhance environmental stewardship in industrial practices.