Guwahati: In a groundbreaking development, researchers at the Institute of Advanced Study in Science and Technology (IASST), an autonomous institute of the Department of Science and Technology (DST), Government of India, have introduced a pioneering method for directly synthesizing Carbon Nanotubes (CNTs) on glass substrates at a relatively low temperature of 750 °C. This breakthrough technique could have far-reaching implications for energy research, biomedical applications, and optoelectronics.

Carbon Nanotubes have long been recognized for their exceptional properties and have found applications in diverse fields, including rechargeable batteries, flexible electronics, aerospace, transparent electrodes, touch screens, supercapacitors, and medicine. However, conventional methods of CNT synthesis involve high temperatures (~1000 °C) and the use of metal catalysts (Fe, Co, and Ni), which raise concerns for biocompatibility, especially in potential biomedical applications. Additionally, the process of removing these catalysts from CNTs incurs significant costs, prompting the need for cleaner and more sustainable synthesis methods.

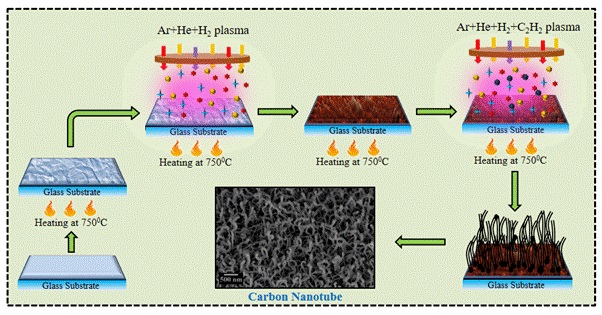

The researchers at IASST have successfully addressed these challenges by developing a novel method utilizing the Plasma Enhanced Chemical Vapour Deposition Technique (PECVD). This technique involves the generation of plasma using a specially designed spiral-shaped fused hollow cathode source, enabling the direct synthesis of CNTs on glass substrates at a significantly lower temperature of 750 °C. Importantly, this innovative process eliminates the need for elevated temperatures and does not require a transition metal catalyst. Furthermore, the synthesis is performed under atmospheric pressure, contributing to cost-effectiveness compared to existing methods.

Several key factors, including plasma characteristics, substrate composition, substrate temperature, and plasma pre-treatment, play a crucial role in influencing CNT growth in this method. Notably, the pre-plasma treatment of the glass substrate at an elevated temperature enhances the surface area, exposing a larger amount of its constituent elements directly to the surface. Among these elements, sodium (Na) has emerged as the primary catalyst for initiating CNT growth, as confirmed by analysis. Interestingly, the study also found that the sodium present in the as-grown CNTs can be easily removed by washing them with deionized water.

In essence, this research presents a groundbreaking atmospheric pressure PECVD process for synthesizing CNTs, offering clean and sustainable CNTs suitable for applications in energy research, biomedical fields, and optoelectronics. The findings represent a significant leap forward in overcoming challenges associated with CNT synthesis, opening new avenues for their utilization in various technological domains.